Sheet metal shell processing is an important metal processing technology, widely used in various industries, such as electronics, communications, automobile manufacturing and so on. Sheet metal enclosure not only has a beautiful appearance, but also can provide good protection and support to improve the reliability and service life of the product. This article will introduce the basic process and characteristics of sheet metal shell processing.

I. Basic Process of Sheet Metal Shell Processing

Design Phase

First of all, it is necessary to design according to the product requirements to determine the shape, size and material of the sheet metal shell. Designers need to select the appropriate materials and processing technology according to the characteristics and requirements of the product, and draw the corresponding drawings.

Shearing and discharging stage

According to the requirements of the drawings, use the shearing machine or laser cutting machine to cut the sheet metal into the required shape and size. Quality inspection is required after the completion of cutting to ensure the cutting quality and precision.

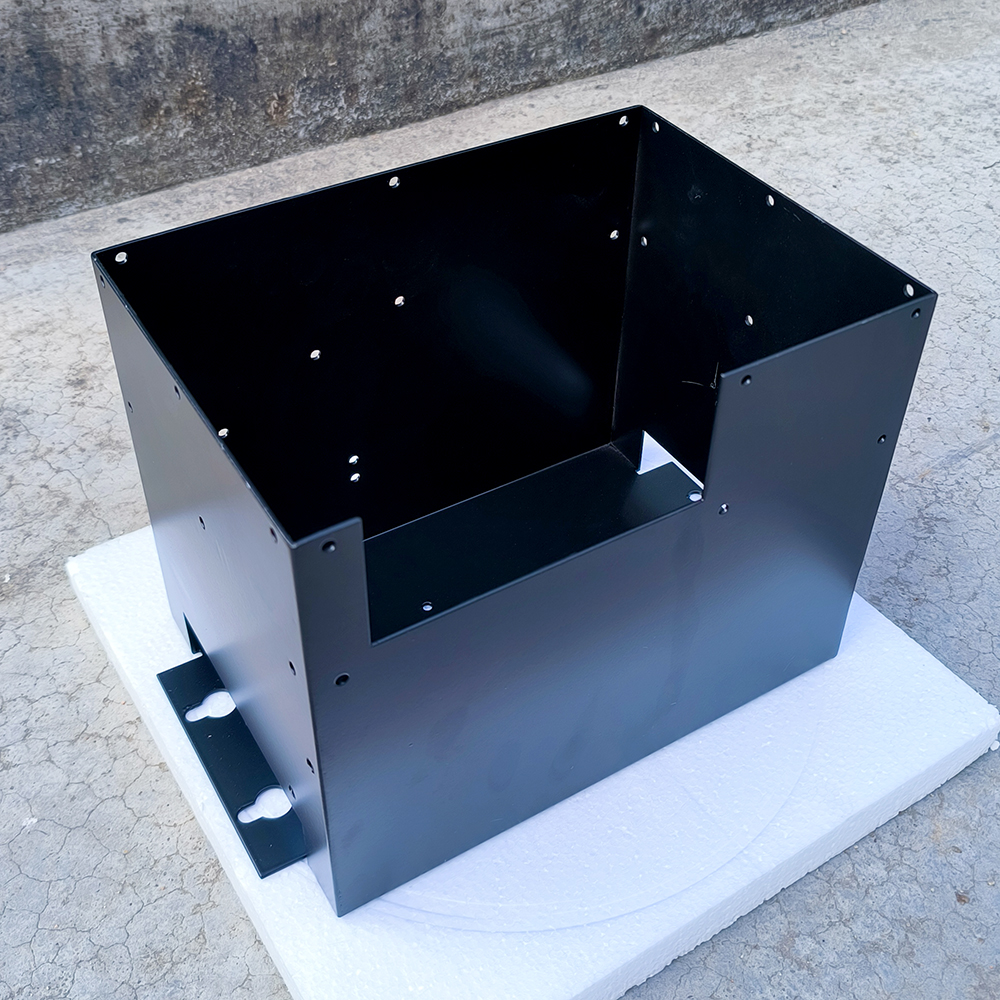

Bending and molding stage

Bend the sheet metal through the bending molding machine. In this process, we need to pay attention to the control of bending radius and bending angle and other parameters to ensure the quality and precision of molding.

Welding and assembly stage

After bending, the sheet metal is welded and assembled to form a complete sheet metal shell. During the welding process, it is necessary to pay attention to controlling the welding temperature, welding time and welding pressure and other parameters to ensure the welding quality and precision.

Surface treatment stage

Finally, the sheet metal shell for surface treatment, such as spraying, plating, etc., to improve its aesthetics and anti-corrosion properties.

II. Characteristics of Sheet Metal Shell Processing

High precision: advanced equipment and technology are used in the processing of sheet metal shell, which can realize the high precision processing requirements.

High aesthetics: Sheet metal shells have smooth surfaces and regular shapes, with a high degree of aesthetic appearance.

High strength: Sheet metal casing has been strengthened by many processes during processing, which has high strength and rigidity.

Corrosion resistance: The surface treatment of the sheet metal shell can improve its anti-corrosion performance and prolong its service life.

Customization: Sheet metal housings of different shapes, sizes and materials can be customized according to customers’ needs to meet individual requirements.

In conclusion, sheet metal shell processing is an important metal processing technology with wide application and market prospects. With the continuous progress of science and technology and the continuous development of industry, sheet metal shell processing will be applied and developed in more fields.

Post time: Dec-12-2023