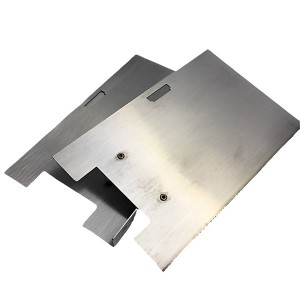

Sheet metal frame customization

-

Custom Steel Stainless Steel Laser Welding Services

Our stainless steel laser welding, laser cutting services, tube bending and other processes customized to reach the industry’s first-class level, can ensure that you provide products, produced out of strong and durable, beautiful and generous appearance

-

Sheet metal cutting stainless steel fabrication services

We specialize in custom processing, using high quality stainless steel materials to create a strong and reliable frame structure. Precise cutting and fine welding provide stable support for your project, showing the perfect combination of quality and taste.

-

Custom sheet metal laser welded stainless steel fabrication

Customized sheet metal processing, stainless steel frame is strong and beautiful. Our factory uses high quality steel and combines it with exquisite craftsmanship to customize each steel frame. Whether it’s for home or commercial use, it will meet your needs and show high quality and durability.

-

OEM sheet metal welded stainless steel box fabrication

We utilize high-precision laser welding technology to create large metal structures that are strong, reliable, precise and detailed. Superior materials and advanced technology ensure superior performance and long-lasting durability. Choose us to make your merchandise a symbol of quality and strength, providing solid support for your projects!

-

OEM Custom Metal Fabrication Stainless Steel Box Fabrication

We utilize high-precision laser welding technology to create large metal structures that are strong, reliable, precise and detailed. Superior materials and advanced technology ensure superior performance and long-lasting durability. Choose us to make your merchandise a symbol of quality and strength, providing solid support for your projects!

-

OEM Custom Stainless Steel Frame Welded Sheet Metal Service

Precise customization, excellent quality. Professional sheet metal processing, our factory creates all kinds of sheet metal processing parts with exquisite laser cutting, laser welding, bending, drawing, polishing, powder coating and other processes to meet your diverse needs. Sturdy and durable, beautiful and generous, make your products more outstanding.

-

OEM ODM Custom Metal Welding Sheet Metal Cutting Service

Professional sheet metal processing with precise customization and superior quality. Our factory creates all kinds of sheet metal processing parts with exquisite laser cutting, laser welding, bending, drawing, polishing and powder coating to meet your diversified needs. Sturdy and durable, beautiful and generous, make your products more excellent and outstanding.

-

OEM custom cut and welded electrical box enclosure service

We have a high level of engineers as well as the industry’s first-class professional machines, to provide high-quality precision laser cutting bending stamping sheet metal processing customized services, to meet your requirements for high quality products, so that your products become excellent.

-

OEM Large Structural Stainless Steel Fabrication Services

We utilize high-precision laser welding technology to create strong, reliable, precise and detailed large metal structures. Superior materials and advanced technology ensure excellent performance and long-lasting durability. Choose us to make your goods a symbol of quality and strength and provide solid support for your projects!

-

OME/ODM custom sheet metal housing laser cutting and welding

We customize fabrication with the same bending, laser cutting, laser welding, and other superb craftsmanship to meet your different needs. Choose us to make your products stronger and more beautiful, and provide reliable support for your products.

-

OEM/ODM Laser Welding for Sheet Metal Processing Parts

High-end custom sheet metal processing, one-stop fabrication, first-class service system and first-class processing and production team, we can meet your high standards for products, so that your products are better than ever!

-

OEM/ODM Customized Sheet Metal Welding Laser Cutting

We use advanced laser technology to cut stainless steel with high precision, ensuring smooth edges and precise dimensions for sheet metal parts. Stainless steel laser cutting, sheet metal parts precisely formed. Customized processing to meet your various needs, excellent quality and trustworthy.