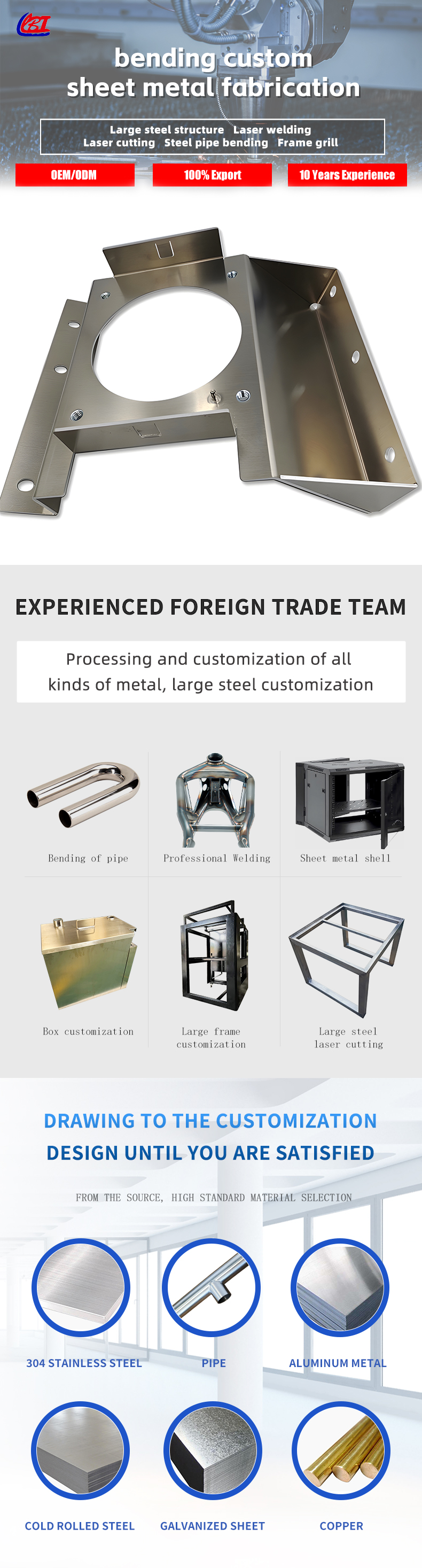

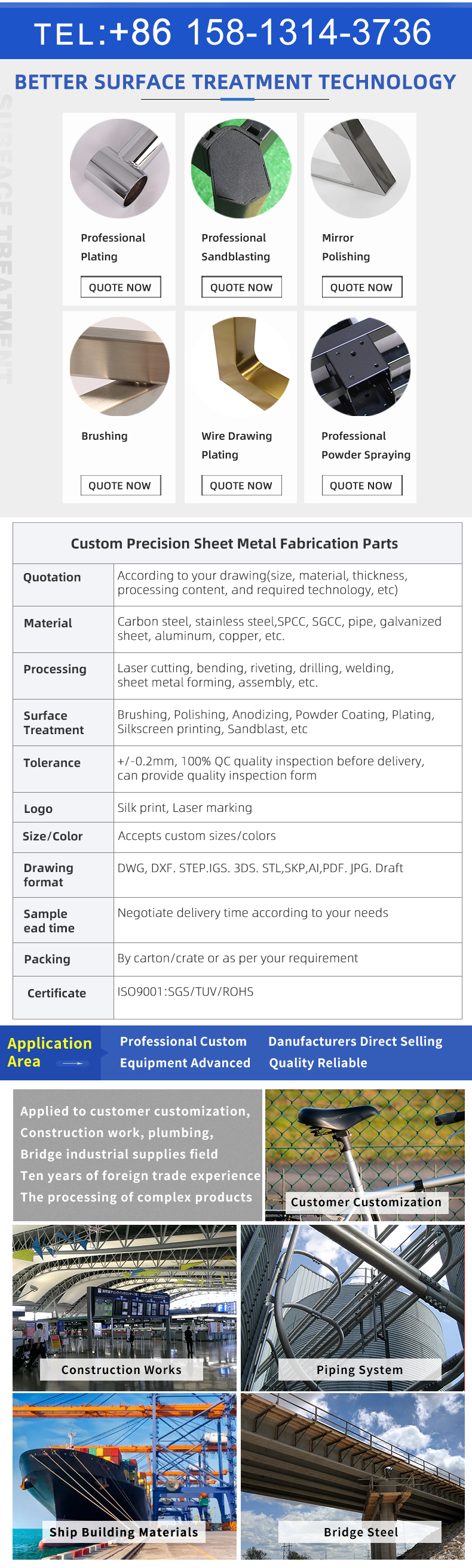

Customized sheet metal processing is a processing method tailored to customer needs. It can meet customer needs for sheet metal products of specific shapes, sizes and materials. The sheet metal custom processing process usually includes the following steps:

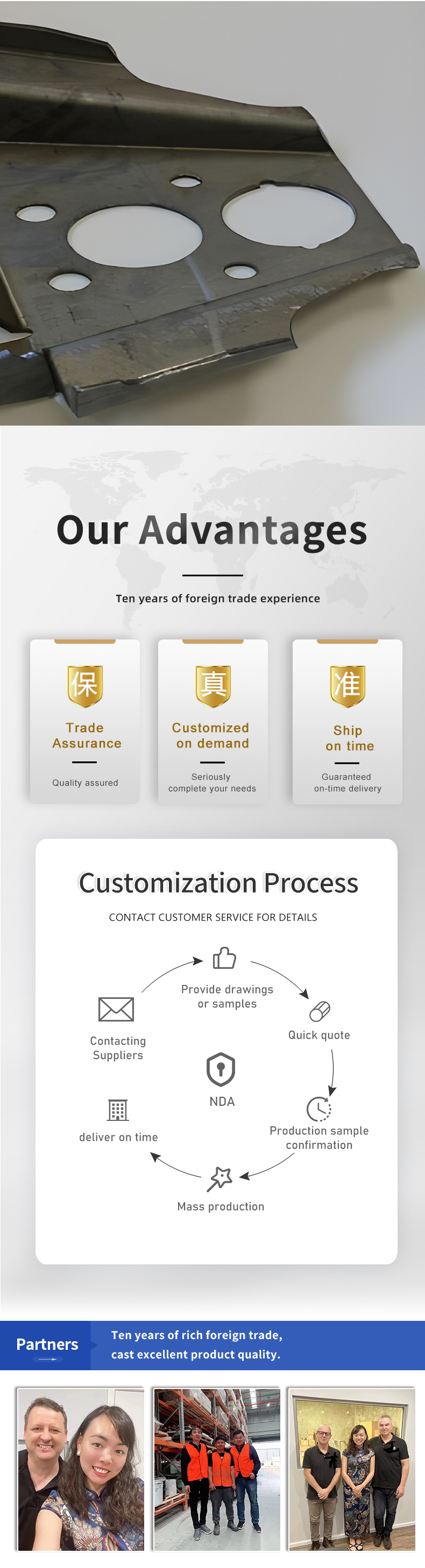

1. Confirmation of customer requirements: First, customers need to provide detailed sheet metal product requirements, including size, shape, material requirements, etc. This information will form the basis for custom processing, ensuring the final product meets customer expectations.

2. Design and engineering evaluation: After confirming customer needs, the sheet metal processing factory will conduct design and engineering evaluation. The design team will formulate a design plan for sheet metal products based on the needs provided by the customer, and conduct an engineering assessment to determine the processing technology and required equipment.

3. Material procurement and preparation: According to the design plan, the processing plant will purchase sheet metal materials that meet the requirements and perform pre-processing processes such as cutting, bending, and stamping to prepare for subsequent processing.

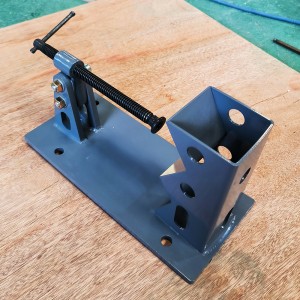

4. Processing and manufacturing: After the material preparation is completed, the processing plant will process and manufacture the sheet metal products. This includes cutting, stamping, bending, welding and other processes, as well as surface treatment and assembly.

5. Quality inspection and adjustment: After processing is completed, sheet metal products will undergo strict quality inspection to ensure that the products meet customer requirements and standards. If necessary, adjustments and corrections will be made to ensure product quality.

6. Delivery and after-sales service: Finally, the processing plant delivers the completed sheet metal products to the customer and provides after-sales service. Customers can install, maintain and service the products as needed, and the processing plant will also make improvements and optimizations based on customer feedback.

In general, the sheet metal custom processing process is a systematic project from customer demand confirmation to product delivery, which requires the coordination of design, engineering evaluation, material preparation, processing and manufacturing, quality inspection and after-sales service. Through this process, processing plants can provide customers with customized sheet metal products that meet their needs and meet the needs of different industries and fields.